Dirt Late Models Crate

Dirt Late Model Newsletter

SHOCK DYNO TESTING SERVICE

Now that the racing season is over, this is the ideal time to start preparing for next season. Many of our customers send all their shocks in to be dynoed at this time of the year, so that they can be checked after a long season of racing. To encourage all our customers to assess their shocks’ condition before the next season, we’re offering a reduced cost for shock dyno services on any A.R.S. shock—only $10 per shock until January 31, 2024. This reduced shock dyno offer will give you a chance to evaluate the condition of your shocks after a season of racing and at the same time review any new valving combinations.

When sending your shocks to us for service, please enclose a note with return address, phone number, and a brief description of what you would like done to your shocks. A shock maintenance form is available from our website. After the shocks are dynoed, we can call you with the results and discuss the outcome of your shocks or any new shock combinations. Many customers send all their shocks to us during this special dyno offer, so send your shocks in as early as possible to avoid any delays in preparing for next season.

Left rear shock and spring combination.

The left rear back compression adjustable base valve shock in conjunction with the left rear front mounted to the axle tube is the best combination for forward bite. A soft left rear back spring (50 lbs. or 80 lbs.) with the proper extended load provides maximum traction when the left rear suspension is up against the limiter chain.

Right rear double spring combination

The double right rear spring combination is nothing new, but many racers don’t know how good it works on a dry slick track. The less right rear load and the harder the compound tire, the better it works. When the right rear radius rods drive the frame up, it unloads the right rear spring. Which in turn dramatically reduces the load on the right rear tire. This is good for heavy tracks but kills the side bite and forward traction on dry slick tracks. The lighter secondary spring keeps loaded when the main spring becomes unloaded. Now that front suspensions don’t rise like the chassis of the past, right rear grip is more important than ever.

Valving Updates

Left Front

There are a couple of things that need to be addressed in the left front shock dampening. The rebound holds cross weight in the chassis, which creates forward bite. Too much rebound pulls the tire off the ground and makes the chassis push mid-corner to exit. The rebound dampening requirements change on a short tight corner track versus a fast-sweeping corner track.

The compression on the left front is adjusted for corner entry. If the chassis is tight on corner entry, you need to soften the compression. When the track dries out and your chassis gets free on entry, you stiffen the compression. After we dyno your shock, we will send you dyno sheets showing your complete adjustment range. We will mark your dyno sheets to show you how to adjust your shocks to accommodate changing track conditions.

Right Front

The right front is possibly the most important shock on the car. The rebound dampening in this shock controls the chassis attitude throughout the corner. Too much rebound hurts forward bite, and too little rebound unloads this corner creating a push condition. It is important to have enough low speed rebound to hold attitude but not too much high speed that it makes this corner too rigid.

The low-speed compression needs to be soft enough to allow the chassis to get down on corner entry and enough high speed to keep the chassis from slamming the bump stop on corner entry. We have built special pistons just for the right front shock to accomplish these requirements.

This corner is very critical of shock and body lengths for different chassis builders. The right front shock body needs to hit the bump stop at the right time and rate. We can set the bump stop and spring load for you with our spring smasher while we are servicing your shocks.

Right Rear

The right rear shocks have a new valve curve that creates more traction than ever before but still creates enough high-speed control to run the cushion. This shock now has more high-speed control to stop the oscillation in the rough. This has always been the challenge to provide both requirements. The rebound range allows you to soften the rebound enough for heavy track conditions and then stiffen the rebound for maximum traction. After we dyno your right rear shock we will send you dyno sheets showing your complete adjustment range. We adjust this shock more than any shock on the car to accommodate changing track conditions. We now change the right rear spring load more than ever. The standard is a 225 spring with spring rubbers, or many customers prefer the double spring (inner & outer) combination for dry slick conditions. Whatever your spring combination is you need to stay on top of your load numbers as track conditions change throughout the night to create the correct balance.

Left Rear

The left rear (behind) shock and spring combination has become more critical than ever before with the requirements on this corner of the race car. It is necessary to have a soft ride height rate so the chassis sets down to get the spoiler through tech inspection. Then have the correct extended rate to provide maximum traction. We can create this spring combination with the triple stack springs. Every chassis manufacturer has different heights and load requirements. We can create a good combination for you regardless of the brand of chassis that you are racing. This shock is normally a compression only adjustable base valve shock.

The left rear front mounted to the axle tube (clamp) shock provides enough extended rate to hold the left rear up and make sure the left rear corner does not fall and let the chassis lose the rear steer. A fine balance of compression dampening and gas pressure provides this combination. This shock’s main function is to create traction from the axle tube rotation. This shock is very critical in making sure you have the correct combination to develop maximum traction. Some racers remove this shock in fast/heavy conditions because it will make the chassis tight in the middle of the corner and on corner exit. This shock is a compression only base valve shock.

Fifth coil

The secret to this unit is to have a stiff rate for instant traction but create enough travel (3” to 3-1/2”in the slick) to make the torque arm pick up the chassis and plant the tires in the track. If you have less than 3” of travel, your chassis will not have maximum traction. We create this combination with the P/D fifth coil assembly. The 1st inch of travel is the stiffest rate with the 2nd and 3rd inch of travel getting softer for maximum travel. We have been running this unit for years, but it is high maintenance and if it is not clean, it will not work. We have just built new sliding floaters that are more dirt and dust friendly. We recommend dry graphite spray to be used on the moving parts after cleaning. We can update all old units with these new floaters and make this unit much more reliable. These shocks are available in rebound adjustable or non-adjustable models.

All chassis builders are making the frames stiffer and out of better tubing to make cars more repeatable throughout the season. This makes the shock dampening and spring rates (load rates) even more critical.

Left Rear Shock and Spring Assembly

Eliminates the Need for Left Rear Front Shock

The triple spring combination provides enough extended load to keep the left rear corner up throughout the corner.

The three spring rates lets the left rear corner drop at ride height to allow for maximum spoiler height.

Now the only need for a left rear front shock is an extremely rough track. For these circumstances, install your left rear front shock in full soft position to navigate through the rough conditions.

The left rear shock is available in single or double adjustable. The compression is fine-tuned to help keep the left rear up throughout the corner.

When ordering this combination, know what your extended and ride height shock bolt to shock bolt is on your current left rear back shock.

P/D 5th COIL SHOCK ASSEMBLY

The Base of the P/D 5th Coil Shock is a Non-Adjustable Small Body Twin Tube 1000 Series Shock.

The compromise of choosing the correct spring for off the corner traction or straight-away traction is over. With the Progressively/Digressive fifth coil assembly you can create the best of both worlds. The P/D unit mounts in the same positions as the conventional fifth coil assembly.

The Problem: A stiff fifth coil springs provides instant traction when the driver starts to pick-up the throttle off the turn, but loses traction halfway down the straight-away, because the rear tires break loose from too much spring rate. A soft fifth coil spring does not hook the rear tires to the ground instantly off the turn, but does provide good traction down the straight-away.

The Cure: The P/D was designed to provide better forward traction off the turn and all the way down the straight-away. The P/D assembly has maximum spring rate the 1st inch of travel, and from 1 inch to 4 inches of travel the spring rate decreases to provide a softer total spring rate. For example a standard 400.b. fifth coil with 3 inches of travel would have a total rate of 12oolbs. The P/D assembly using a 400/300 spring combination with 3 inches of travel would have a total rate of 926lbs.

The P/D assembly is a combination of two springs with a slider assembly held together with a small diameter shock in the center. For the first inch of travel, the fifth coil assembly primarily uses the long spring. After that the additional travel uses the combination of both springs providing the desired spring rate. A small diameter shock in the center of this assembly dampens the spring to control any undesired oscillation.

The Disclaimer: The P/D fifth coil assembly is not a cure for all ill-handling race cars. It will increase forward bite over a standard fifth coil assembly, but it will not take a race car that has poor forward bite because of a bad rear suspensions combination and make a winner out of that car.

Double Bump Spring for Right Front of Dirt Late Model

The double bump spring allows you to have a dual stage bump spring rate, to keep the front end down. Now you can be as soft as possible, as long as possible, without bottoming out on the cross member.

The outer spring starts compressing the last 1” of travel of the right front. The inner spring engages the last 1/4” to 3/8” of travel. This allows the spring combination to travel more without coil binding the bump spring.

This bump spring package provides 500 lbs. of outer rate at 1” of travel. The inner spring allows up to 600 lbs. of rate the last 1/4” of shock travel. The spring cups provide support for the bump springs.

This system will not work on all shock bodies. You must have 6-1/2” of shock shaft available at ride height.

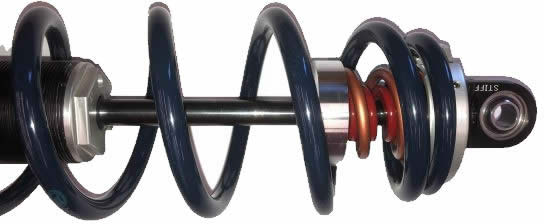

Double Spring Combination – Right Rear

The double spring right rear uses a 10” x 100 lbs. inner spring with a 12” x 150 lbs. barrel outer spring. This package provides more forward bite and side bite than a standard 250 lb. spring or 225 lb. with spring rubbers. This unit will provide the same entry rate as a single spring but will have a softer exit rate. The right rear dual springs provide more pressure pushing the tire into the race track. This is achieved by pre-loading the 100 lb. inner spring so pressure is applied even on extension as the car is driving off the corner.

This is designed for dry slick only, middle to bottom of the race track. It will make the chassis tight if the right rear tire hits the cushion. The slicker the track the better this works.

Example of standard right rear versus double spring:

Right rear shock Travel 225 lbs. spring + Double spring

center to center 1 rubber (250 lbs. rate) 100 lbs. + 150 lbs.

21-1/2” 1-1/2” extended 25 lbs. load 224 lbs. load

21” ______1” extended 150 lbs. load _ ____280 lbs. load

20” ride height 400 lbs. load 400 lbs. load

19” 1” compression 650 lbs. load 650 lbs. load

18” 2” compression 900 lbs. load _900 lbs. load

Bump Stop For Droop Limiter

1″ tall x 2 1/2″ O.D. with 9/16″ center hole for the 2020 World of Outlaws droop stop rule. These straight side bump rubbers fit in most current droop limiters.

Available in (4) durometers and colors.

Black – 30 durometer

Yellow – 40 durometer

Orange – 50 durometer

Blue – 60 durometer

Package 1 – $3,650

($3,890 with Four C/O Kits)

Fronts – 4200 Series Mono Tube E-Model (Rebound) Adjustable

Left Rear Front – 4200 Series Mono Tube E-Model (Compression) Adjustable

Left Rear Back – 4200 Series Mono Tube E-Model (Rebound) Adjustable

Right Rear – 3200 Series Mono Tube E-Model (Rebound) Adjustable

P/D Fifth Coil

Fronts

The 4200 Series shock is a large body mono-tube (gas) shock with a hard black anodized aluminum body. This shock uses CNC machined aluminum internal parts designed for racing with no aftermarket parts. These shocks contain the latest T/C valving with a large diameter flat line piston for maximum front grip. They are E-Model Eye (Rebound) Adjustable that include the new style adjusting wheels that allow the eyes to be removed easily to change bump stops. This shock utilizes a base valve that is installed between the floating piston and the valving piston to isolate the pressure, allowing for substantial reduction in rod pressure. These rebound adjustable shocks contain check valves to ensure no bleed-over when adjusting the rebound dampening. This shock has a Schrader valve that provides for fine tuning the gas pressure. This shock accepts 2 ½” I.D. or 5” O.D. Springs and is available in 5”, 6”, 7”, 8” & 9” shaft lengths.

Left Rear Back

The 4200 Series shock is a large body mono-tube (gas) shock with a hard black anodized aluminum body. This shock uses CNC machined aluminum internal parts designed for racing with no aftermarket parts. This shock contains the latest T/C valving with a large diameter flat line piston for maximum front grip. This shock is E-Model Eye (Rebound) Adjustable that includes the new style adjusting wheels that allow the eyes to be removed easily to change bump stops. This shock utilizes a base valve that is installed between the floating piston and the valving piston to isolate the pressure, allowing for substantial reduction in rod pressure. This rebound adjustable shock contains a check valve to ensure no bleed-over when adjusting the rebound dampening. This shock has a Schrader valve that provides for fine tuning the gas pressure. This shock accepts 2 ½” I.D. or 5” O.D. Springs and is available in 5”, 6”, 7”, 8” & 9” shaft lengths.

P/D Fifth Coil

The Base of the P/D 5th Coil Shock is a Non-Adjustable Small Body Twin Tube 1000 Series Shock. The P/D assembly is a combination of two springs with a slider assembly held together with a small diameter shock in the center. For the first inch of travel, the fifth coil assembly primarily uses the long spring. After that the additional travel uses the combination of both springs providing the desired spring rate. A small diameter shock in the center of this assembly dampens the spring to control any undesired oscillation.

Left Rear Front

The 4200 Series shock is a large body mono-tube (gas) shock with a hard black anodized aluminum body. This shock uses CNC machined aluminum internal parts designed for racing with no aftermarket parts. This shock contains the latest T/C valving with a large diameter flat line piston for maximum front grip. This shock is E-Model Eye (Compression) Adjustable that includes the new style adjusting wheels that allow the eyes to be removed easily to change bump stops. This shock utilizes a base valve that is installed between the floating piston and the valving piston to isolate the pressure, allowing for substantial reduction in rod pressure. This compression adjustable shock contains a check valve to ensure no bleed-over when adjusting the compression dampening. This shock has a Schrader valve that provides for fine tuning the gas pressure. This shock accepts 2 ½” I.D. or 5” O.D. Springs and is available in 5”, 6”, 7”, 8” & 9” shaft lengths.

Right Rear

The 3200 Series shock is a small body mono-tube (gas) shock with a hard black anodized aluminum body. This shock uses CNC machined aluminum internal parts designed for racing with no aftermarket parts. This shock is rebound adjustable valved for maximum traction with the latest T/C valving. This shock is E-Model Eye Adjustable. The base valve design in this shock allows for very low gas pressure to be used and still function properly. This shock gives the driver more feel and allows the car to grip the track more. This shock has a Schrader valve that will accept 10-50lbs. gas pressure which provides for fine tuning the chassis balance. The small body shock accepts 1 7/8”, 2 ¼” & 2 ½” I.D. Spring & is available in 5”, 6”, 7”, 8” & 9” shaft lengths.